resource library

Array

Mordialloc Industrial Precinct

The site abuts Mordialloc Creek

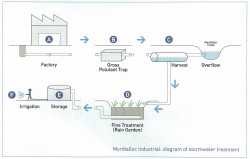

Schematic of stormwater treatment train and harvesting process at Mordialloc Industrial Precinct

Two large gross pollutant traps allow material to be captured before the water enters the storage area.

Underground pipes allow storage of 187kL

This site trials porous material on a road subject to heavy traffic volumes (shown here: interlocking pavers)

Tideflex valves prevent backflow from Mordialloc Creek into the storage area

Mordialloc Industrial Precinct

Kingston City Council

Published: 30 January 2014

Project Overview

The award winning Mordialloc Industrial Precinct project is the first project in Australia where public infrastructure in an old industrial estate has been renewed with the aim of using harvested stormwater as a community asset. In 2005, the site was identified as an opportunity to trial a broad range of solutions within an industrial streetscape. When the drainage network and roads around the site needed to be upgraded to prevent flooding, council took the opportunity to implement a more broad scope of stormwater management features.

The project encompasses a 7ha industrial area located within the City of Kingston (26 km from the Melbourne CBD), which abuts Mordialloc Creek, only 1.5km upstream from Port Phillip Bay. Three roads within the precinct were redesigned to harvest road runoff and stormwater from factory roofs to help protect a nearby creek, irrigate adjacent park and street trees and provide increased flood protection for nearby properties.

In 2012, this project received the IPWEA Vic Award and the Stormwater Victoria Award in the Asset Management Category.

Stormwater treatment train and harvesting process (refer to schematic diagram):

The catchment (A) consists of three industrial roads, which were redesigned to harvest 4ML of stormwater each year from factory roofs and road runoff. The redesign included:

- installing two new drains along Beach Avenue and Spray Avenue

- fitting 54 ‘King Trap’ stormwater pits, specifically developed by the City of Kingston to capture sediment and coarse pollutants, along the roads; and

- covering a 330m2 area of road and carpark with porous pavement material: Both interlocking porous pavers and in situ poured paving were trialled.

Two large gross pollutant traps (B) allow material bypassing the pits to be captured before the water enters the 187kL underground storage system (C), consisting of 61m of 2.4m diameter pipe.

At this point, an outlet into Mordialloc Creek allows for water from large storm events to bypass the treatment system. Due to the very flat site and the outfall being located below sea-level, the outlet was equipped with an innovative rubber valve to prevent backflow during high tide.

After initial storage, the water is pumped into a 180m2 bioretention system (raingarden D), consisting of layers of engineered soil and sand. The plants in the raingarden treat the water by removing metals and nutrients.

The treated water is then pumped back up into an above-ground 240kL storage tank (E), where it can be used for irrigation of street trees and a nearby turf wicket.

Drivers and Objectives

- Save potable water by providing an alternate water resource for irrigation

- Increase flood protection for adjacent properties

- Protect waterways by preventing harsh pollutants from discharging directly into Mordialloc Creek

- Improve amenity of the old industrial estate

- Overcome site specific constraints such as:

- existing infrastructure including the Esso oil pipeline

- below sea-level outfall into Mordialloc Creek

Organisations

City of Kingston (Responsible Council)

Australian Federal Government (Funding Partner - $70K or 50% of the cost of the storage & reticulation system)

Melbourne Water (Partner in the review of stormwater quality treatment devices)

Cardno Group (Partner in the review of stormwater quality treatment devices)

AECOM (Partner in the development of the ‘Project Scoring’ system)

Project Outcomes

Some of the outcomes of the project include:

- 4ML of harvested stormwater available for irrigation of nearby green spaces and sport fields

- Increased flood protection for adjacent properties

- Reduced volumes of polluted stormwater discharging into receiving waters

- Improved amenity in the industrial estate through direct (e.g. raingarden) and indirect (e.g. greener street trees and ovals) benefits

- Improved community awareness and knowledge (both in the wider community and for the factory workers on the project site) through engagement activities including:

- Community consultation on their ‘vision’ for improving Mordialloc Creek (2010)

- ‘Door knocking’ every factory in the catchment as part of an education campaign, to explain ways that they could reduce the volume of pollutants leaving their site

- Installation of two large information signs on-site

- Circulation of project information bulletins and advertising in local newspaper and on Council’s website

In addition to the specific project outcomes, this project was the catalyst for the realisation of two related projects, whose outcomes can be used to assist with many future proposals:

- A unique Water Sensitive Cities ‘Project Scoring’ system was developed to help managers understand the broader benefits and compare competing Water Sensitive projects as part of business planning and funding decisions (see scoring card in attachments).

- The design of the stormwater harvesting system also brought about a major review of stormwater quality treatment devices to compare performance, durability, maintenance requirements, whole-of-life costs and overall suitability for industrial streetscapes. Whilst the recommendations are specific to this project, some of the findings could be useful to assist decision making on other similar industrial projects.

Finally, this project was used as an opportunity to implement and trial new technical solutions:

- Despite existing concerns about their durability and long term performance, the project trials two types of porous materials - interlocking pavers and poured in situ paving - within a road subject to heavy semi-trailer and forklift traffic volumes. The performance will be monitored over 5 to 10 years, however the interlocking pavers seem to be performing well, despite some cracking observed at the interface with the adjoining asphalt pavement.

- This project is also trialling an innovative double-side entry pit to act as a primary pre-treatment system. The ‘King Trap’ (Kingston Pollutant Trap) was developed as an alternative low cost, practical and effective pit that is extremely simple, robust and easy to maintain. It uses permeable pavers as a removable vertical wall to help separate silt and gross pollutant. Initial observations show that whilst the pollutant removal is likely to be slightly lower than more sophisticated products, the robustness is high and the cost is low.

- Innovative Tide Flex fittings were installed at the outfall into Mordialloc Creek to prevent backflow during high tide, which would otherwise contaminate the harvested water. Whist these valves are very effective, providing excellent long term value for money, they are also very expensive and need to be imported from the USA.

Lessons Learnt

- One of the key lessons from this project was the need for patience. Indeed, the potential to install a major water quality treatment and reuse scheme at this location was first identified by one of council’s engineers in 2005.

- Developing ongoing relationships with key internal and external decision makers early on proved very useful, as it helped identify opportunities to influence funding decisions.

- The project team developed an effective working partnership with Melbourne Water by involving their experts at an early stage. This resulted in a number of enhancements and the opportunity to obtain a second opinion which influenced the overall scope of works.

- The key driver for this project was the need to improve the road pavement and the traditional drainage system; however the ultimate environmentally friendly solution was a key focus of the initial design and not an afterthought. We found it to be a major advantage for the concept and detail design to be undertaken by someone (in this case an in-house Council engineer) who is both an experienced road designer and who is also experienced in the design, construction and maintenance of WSUD projects.

- From a construction perspective, this project was invaluable in building internal knowledge and expertise. It highlighted the importance of:

o Having a tender assessment model that appropriately values the contractor’s expertise in delivering complex projects as opposed to be driven primarily by price. Not recommending the cheapest tender submission can be challenging when budgets are tight.

o Being prepared to adopt a different project management model and allocate additional resources towards supervision and contract management.

o Identifying a ‘champion’ within Council’s construction team to resolve complex issues and co-ordinate with other stakeholders, specialist contractors and suppliers.

o With projects that include ‘cutting edge’ design features or products, it is critical to explain and educate the contractor about the unique features well in advance. Resolving construction problems ‘on the fly’ will not deliver a successful outcome.

Project Cost

Total project cost: $2.8M, with the following breakdown of cost:

7% Research, design & development

49% Pavement rehabilitation & streetscape works

29% Flood Protection

15% Stormwater treatment and harvesting

Timeframe

2009 Review of existing Stormwater Quality Devices in partnership with Melbourne Water and Cardno

2010 Development of the ‘King Trap’ treatment pit (implemented in 2011)

2010 MUSIC modelling

2011 In partnership with AECOM, development of a ‘project scoring system’ to strengthen the business case.

This system helped confirm project funding arrangements.

2011 Detailed design plans and specifications

2011 Water sampling and testing

2011 Advertise and award tenders for construction

2011 – 2012: Construction

Stage 1: Reconstruction of Beach Avenue, gross pollutant traps (B) and underground storage system (C)

Stage 2: Reconstruction of Spray Avenue and Wells Road (including porous pavements) and storage tanks

2012 Report on greenhouse gas emissions

2013 Stage 3: Install Bioretention system and pumps

Contact

City of Kingston, Alan West – Team leader engineering design

alan.west@kingston.vic.gov.au

Acknowledgements

All photographs are courtesy of the City of Kingston